Bob thinks he can make a laser cutter.

Labor Day traditionally denotes the end of summer. Kids head back to school, clothing stores start displaying long sleeves and jackets, and makers start their big winter projects.

This winter, I have the audacity to presume that I can build a CNC laser cutter.

I will be basing my design on the Buildlog.net 2.x Laser. I will be following the 2.x plan very closely for the mechanical design, but will deviate in the electronics and software.

There is no kit for the 2.x laser cutter, so my first tasks have been to find sources for the roughly 180 components needed and place orders with the respective vendors.

I actually started ordering parts on August 3rd, and I have received a few parts. And there are many more coming.

So while I wait, here are some pictures of the parts that are already here.

Here are the stepper motors. They are NEMA 17 with double ended shafts. Don’t they look good in their black paint? They came from Automation Technology. Actually, I think they might be the wrong parts — I need motors with 5mm shafts, and these have ¼ inch shafts. If the very first parts are wrong, what are the odds that I’ll actually finish this project? (-:

And here are some couplers, made to order by dumpsterCNC in Delrin™. They couple ¼ inch shafts to 5mm motor shafts. (Too bad I don’t have 5mm motor shafts.)

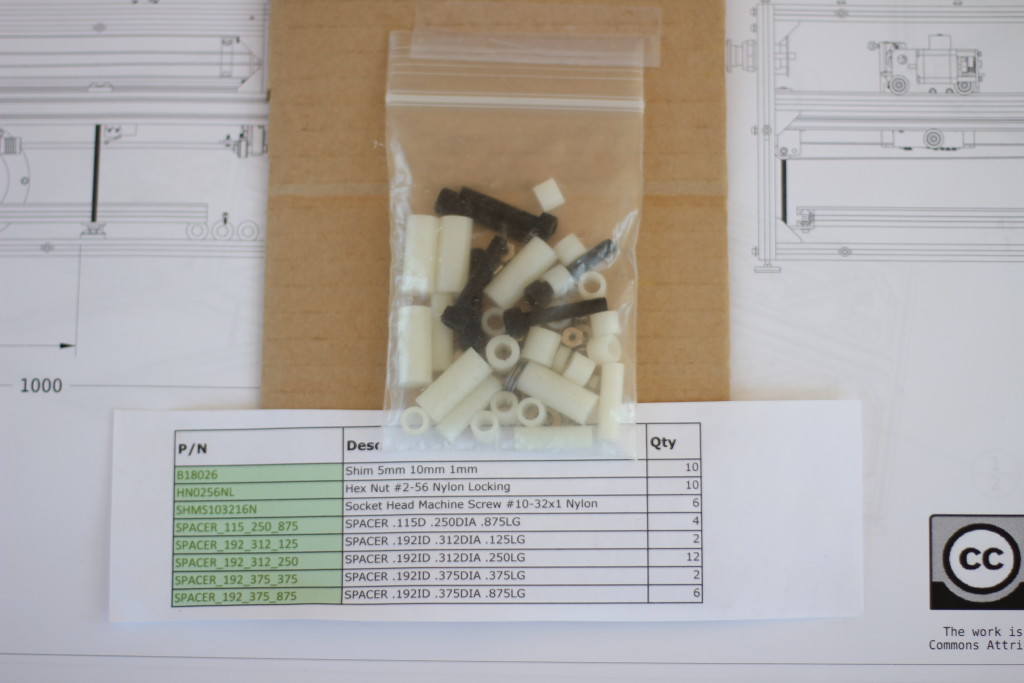

Fellow laser builder Radishworks put together a bag of small parts. He had to buy all these in quantity 50 or more, so he had lots of extras, which he resold. I got one.

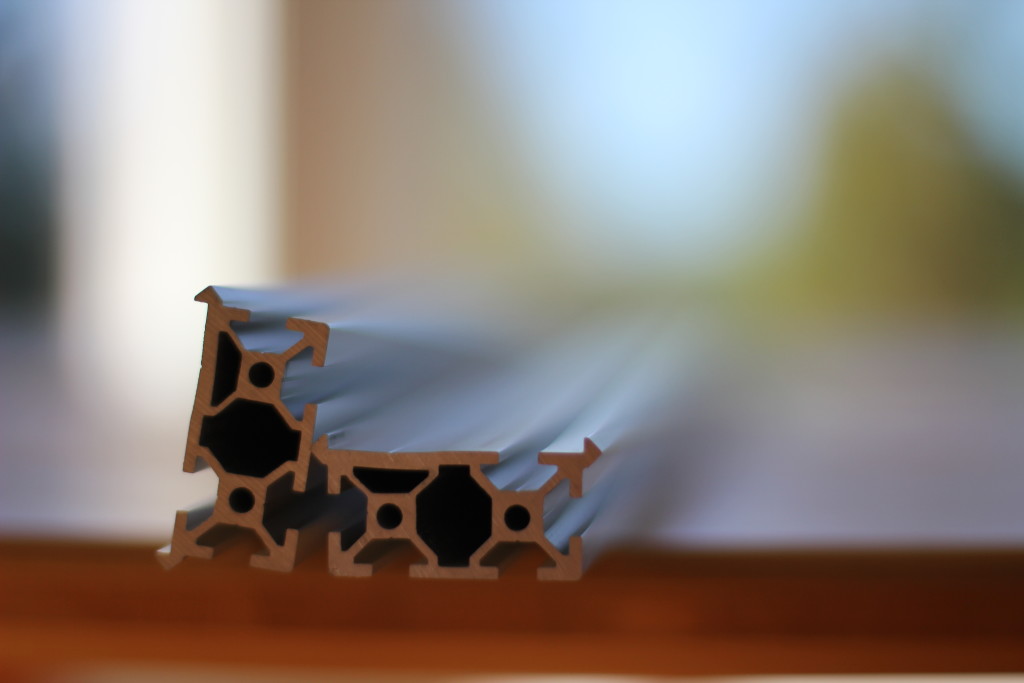

Makerslide. I got two 1200mm lengths (47 inches). It is an ordinary 20x40mm aluminum extrusion, except it has V shaped ridges on two of the corners. (I might have overdone the artistic depth of field thing on this photo. Must use f-stops only for good.)

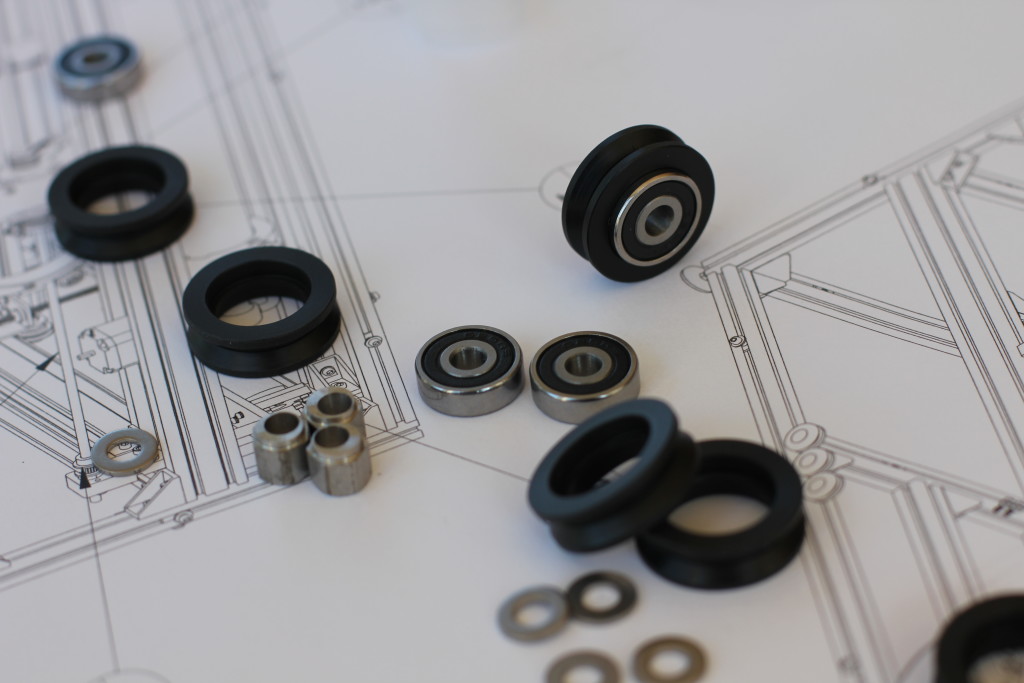

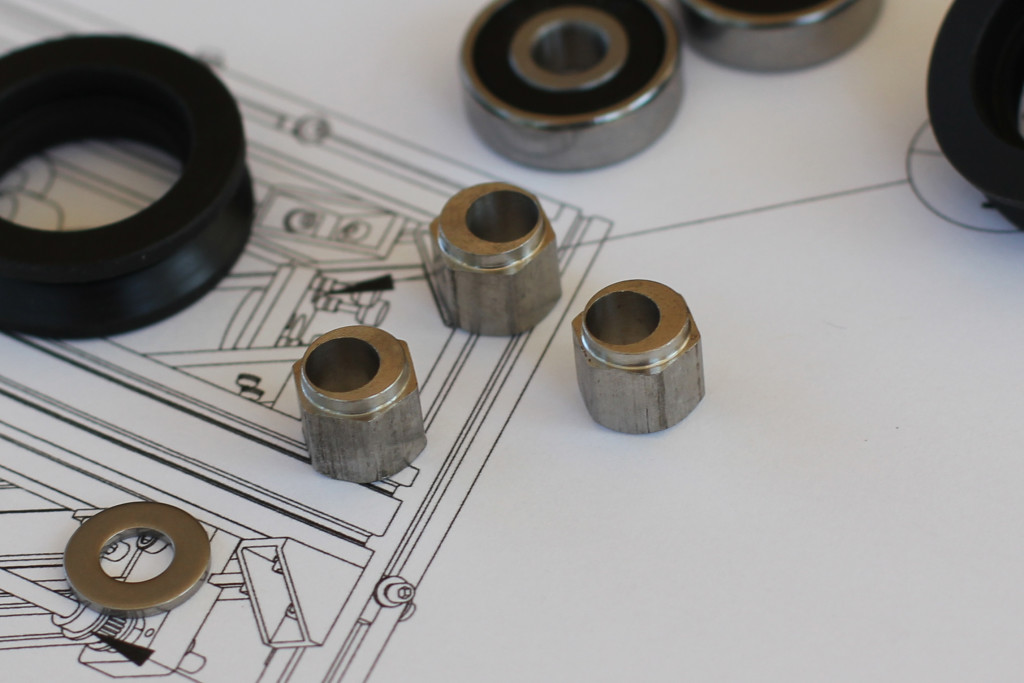

These are dual-bearing V wheels. The wheels ride on the ridges on the Makerslide. They are Delrin™. The bearings fit inside. The washers are sandwiched between the bearings. They keep the bearings separated and add rigidity, I think.

Those little nut things are eccentric spacers. The inner hole is off center. Put the nut’s cylindrical flange into a hole, put a shaft through the center hole, and then rotate the nut to adjust the shaft’s position. These will be used to make the V wheels fit snugly against the Makerslide. The Makerslide, V wheels, and eccentrics all came from Inventables.

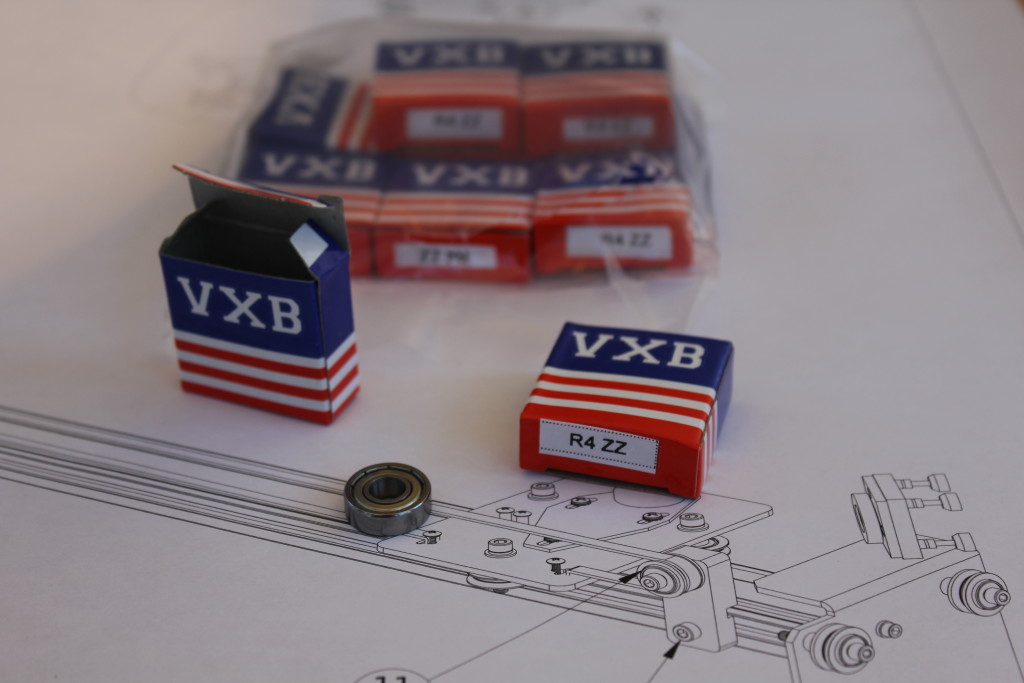

VXB sent me some bearings. They came in patriotic packaging. They are also quite overpackaged: bearing in bag in box in bag with other bearings in envelope. It’s the American Way.

I also got a whole pile of random fasteners and hardware from McMaster Carr. The big metal flange in the center will attach the vent hose to the cabinet. I got the oversize drawings printed at FedEx Office.

Lots more parts are coming. I have confirmed shipping on aluminum extrusion, more fasteners, more V wheels, some drive belts and pulleys, and the optics (mirrors, lens, and bracketry). I have no firm delivery date on cable carriers, microcontrollers, stepper drivers, or a Raspberry Pi.

Finally, here’s Riley, the project manager. He disavows any knowledge of how that table leg got chewed. (Truthfully. He did it in 2009, and has completely forgotten about it.)

More later…

That’s so cool what’s a raspberry pi

Can I help with it

Connor, a Raspberry is a cheap computer that runs Linux.

http://raspberrypi.org/

Conner,

Can you please let me know where you purchased the Delrin V wheels?

Thanks

Josephine, I think I got those wheels from Inventables.

https://www.inventables.com/categories/frame-rail/wheels